TPU色母与PA6色母的基本概述

热塑性聚氨酯(TPU)和尼龙66(PA6)是广泛应用于塑料行业的重要材料。TPU因其优良的弹性、耐磨性及抗油脂性能,常被用于制造鞋底、软管及汽车配件等。而PA6则以强度高、耐温好以及出色的化学稳定性著称,多用于电子产品外壳和机械部件。随着市场需求多样化,这两种材料在某些领域可互换使用,为设计师提供了更多灵活选择。

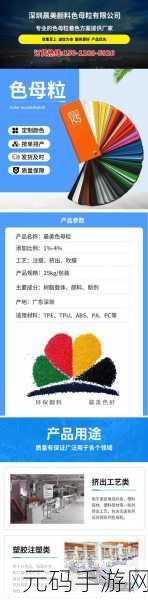

用户需求分析

许多企业希望通过对不同颜色或材质进行定制来吸引消费者目光。因此,在生产过程中,对色母粒的选择显得尤为重要。一方面,客户要求确保所用材料具备相似甚至更好的物理特性;另一方面,他们也关注成本效益,以降低整体生产开支。在这一背景下,将TPU与PA6之间的色母互换成为一种便捷且经济实惠的方法,从而满足不断变化的市场需求。

技术兼容性的考量

尽管TPU与PA6有着各自独特的性质,但它们之间并非完全不可替代。当考虑到加工工艺时,两者在熔融流动指数上的差异会影响成品质量。例如,若要将TPU切换到PA6,需要评估模具温度控制,以及注射压力是否适应新材料。此外,要注意的是,不同品牌或类型间可能存在一些性能偏差,因此需要进行小批量试验,以验证最终产品能否达到预期效果。

环境友好型趋势推动互换发展

Sustainability has become a significant focus across various industries. TPUs are often considered more environmentally friendly due to their recyclability and lower toxicity during production compared to traditional plastics. As companies strive for greener solutions, the shift towards using TPU over PA6 in certain applications becomes increasingly common. This trend not only meets regulatory demands but also resonates with eco-conscious consumers who prioritize sustainability in their purchasing decisions.

案例研究:成功实施实例

A number of manufacturers have successfully implemented the interchange between TPU color masterbatches and PA6 color masterbatches in recent years. One notable case involved an automotive supplier that faced challenges with wear resistance in specific interior components. By switching from PA6-based materials to TPU variants while maintaining similar design aesthetics through color matching, they significantly improved product lifespan without increasing costs substantially.

TPU与PA6调配技术的发展前景

The continual evolution of blending technologies holds promise for enhancing compatibility between different polymers like TPU and PA6. Innovations such as reactive extrusion or advanced compounding techniques can further improve intermaterial bonding, thus allowing greater flexibility when mixing these two types of resins together while preserving desirable attributes like strength and elasticity.